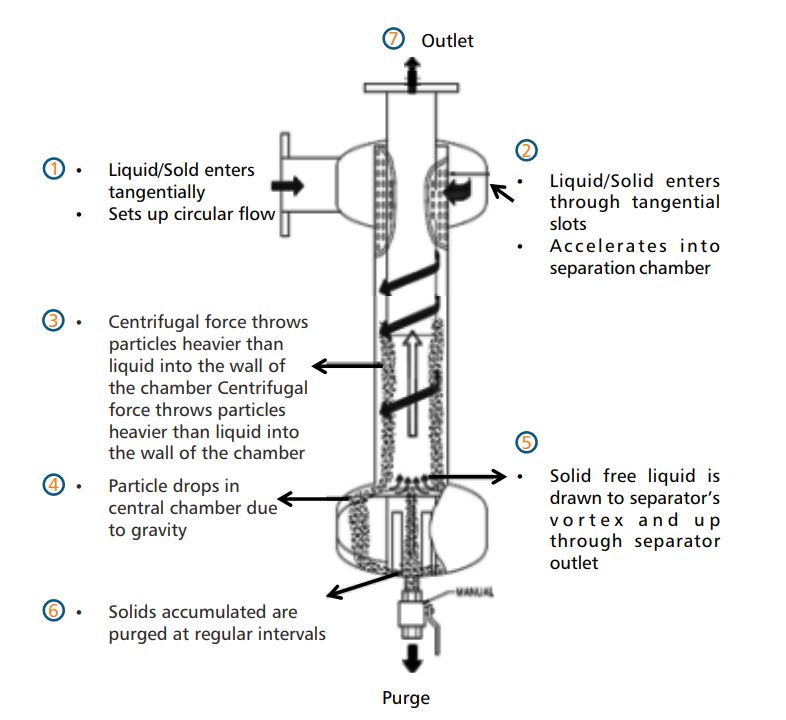

Cyclone, Sand, Centifugal Separator

Cyclone Separators (Sand Separators) are used for separation of sand silica like high density particles from water. Minimum operating pressure of 2 kg/cm is required for smooth functioning as these cyclones work on centrifugal motion, for which positive operating pressure is required. Tangential entry is provided at the inlet which allows water to enter in cyclonic motion. Also inside the vessel particular type of slotted pipe is provided which further accelerates the velocity resulting in heavier particles falling at the bottom. Water being of lighter density exit from the outlet at the top. The bottom has a diverter plate with wave breakers in the collection chamber which allows dirt to settle in the chamber. The drain is

provided with electrical or pneumatic valve and a small control panel with a timer at bottom.

Cyclone Seperator, Sand Seperator & Centifugal Seperator

It is a static equipment apart from motorized valve at the bottom. There is

no mechanical barrier hence there is no maintenance required. The drain

valve timer is normally set between 30 to 60 seconds, duration depends on

the dirt load. There is a normal pressure drop at the inlet and outlet of 0.2 to 0.3 kg/cm and as there is no blockage or choking, the pressure drop

remains continuous during operation.